Flame-retardant fabrics refer to fabrics that can self-extinguish even when removed from an open flame. Flame retardant fabrics can be divided into post-finished flame retardant fabrics and intrinsic flame retardant fabrics (durable flame retardant fabrics). Post-finished flame-retardant fabrics are also post-processed flame-retardant fabrics. They are produced through coating and auxiliary treatment during dyeing and finishing. The flame-retardant effect will gradually weaken after washing. They are generally used to produce things that are not washed frequently.

The combustion test method is mainly used to detect the damage length, afterburning time and smoldering time of the specimen. A test piece of a certain size is ignited with the required fire source in the required combustion box for 12 seconds. After the fire source is removed, the afterburning time and smoldering time of the test piece are tested. After the smoldering stops, measure the damage length according to the prescribed method. Mainly based on the American ASTMF1358-1995 “Standard Measurement Method for Textile Flame Retardant Properties – Vertical Method” and China’s GB/T5456-2009 “Textile Combustion Performance Testing of Flame Spread Performance of Vertical Direction Specimens” and GB5455-1997 “Textile Combustion Performance Test Vertical Method” and other standards. Chinese national standards require afterburning time ≤5s, smoldering time ≤5s, and damage length ≤150mm. According to the relative position of the test sample and the flame, it can be divided into vertical method, tilt method and horizontal method.

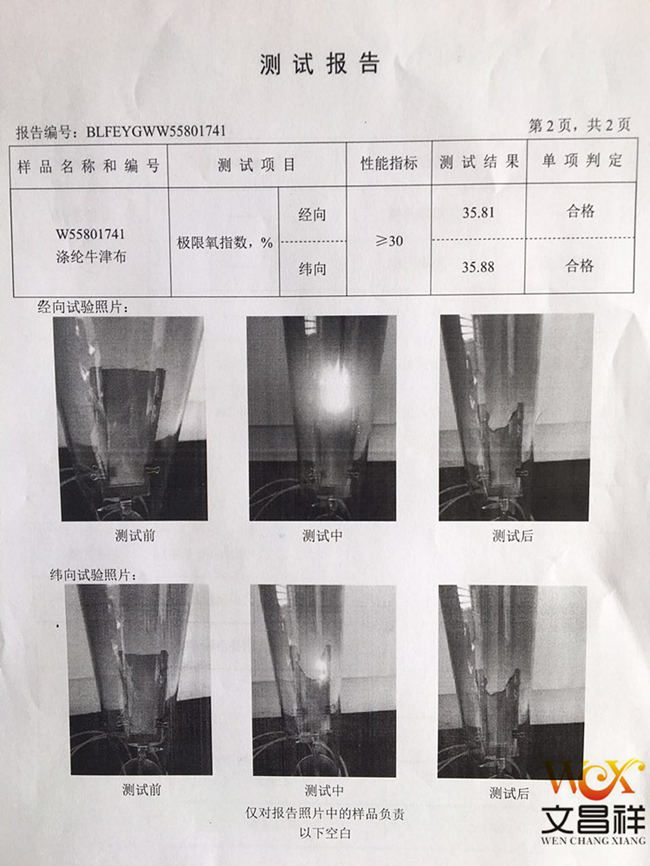

The horizontal method and the vertical method are the more common methods for measuring fireproof materials. The basic principle is: hold one side of the specimen horizontally or vertically, add the required gas flame to the free end of the specimen, and evaluate based on the measurement of the linear burning rate (horizontal method) and the flame and flameless burning time (vertical method) Combustion performance of the test piece. The vertical method test burns more violently than the 45° direction and the horizontal direction. Oxygen index detection method: When the fabric burns, it needs to consume a lot of oxygen. Different combustibles require different amounts of oxygen when burning. Based on the measurement of the amount of oxygen consumed during the combustion process of the material, the oxygen content of the material is calculated. Index value can judge the combustion performance of a substance.

Independently research and develop flame-retardant fabrics. According to different requirements of customers, the following specifications are available: 210D, 300D, 420D, 600D, 900D, 1200D, 1680D Oxford cloth, etc., which have temporary flame-retardant effect, semi- Durable flame retardant effect and durable flame retardant effect can also be provided with waterproof, flame retardant, PVC/PU coating, silver coating, composite and other treatments according to customer needs. You can contact the online customer service on the web page or leave a message. , to meet all your requirements with dedicated service.

</p