Flame retardant fabrics are often realized through the principles of gas phase flame retardant, condensed phase flame retardant and interrupted heat exchange flame retardant. It is a gas phase flame retardant that can freely exert the function of flame retardant fabrics by inhibiting the growth of the combustion reaction chain; it is a condensed phase flame retardant that plays a flame retardant role by delaying or preventing the thermal decomposition of polymers in the solid phase; it can absorb part of the heat generated by burning polymers. The flame retardancy caused by taking away the heat exchanger belongs to the type of flame retardancy that interrupts the heat exchange mechanism.

For example, waterproofing and oil-repellent finishing of polyester flame-retardant fabrics can improve the functionality of flame-retardant clothing; interweaving flame-retardant polyester and conductive fibers to produce antistatic flame-retardant fabrics; High-performance flame-retardant fabrics can be produced by blending flame-retardant fibers with high-performance fibers; blending flame-retardant fibers with cotton, viscose and other fibers can improve the comfort of protective clothing and reduce secondary burns.

The method of flame retardant finishing and modification of polyester fabrics is simple. However, if the amount of flame retardant is large, it will have a greater impact on the feel and color of the fabric. There are roughly three types of flame retardant finishing methods for polyester flame retardant fabrics and nylon flame retardant fabrics:

1. Design the flame retardant into an adsorption structure like disperse dyes, and use finishing-dying One bath process. 2. Use hot melt method to fix the flame retardant that has great affinity with polyester fiber on the fiber. There are not many types of flame retardants suitable for this method, they have little impact on hand feel and have good washing fastness. 3. The dissolving flame retardant is easy to use and has good flame retardant effect. It is suitable for flame retardant finishing of natural and chemical fiber fabrics and papers that are not resistant to washing. It is also suitable for flame retardant finishing of interior decoration materials used in hotels, automobiles, etc.

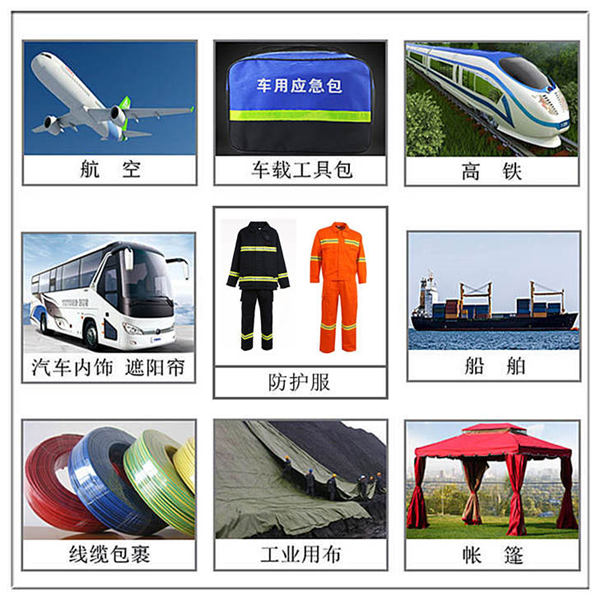

Independently research and develop flame-retardant fabrics. According to different requirements of customers, the following specifications are available: 210D, 300D, 420D, 600D, 900D, 1200D, 1680D Oxford cloth, etc., with temporary flame-retardant fabrics. Effect, semi-durable flame retardant effect and durable flame retardant effect. It can also be equipped with waterproof, flame retardant, PVC/PU coating, silver coating, composite and other treatments according to customer needs. You can contact the online customer service on the web page, or You can leave a message and we will provide dedicated service to meet all your requirements.

</p