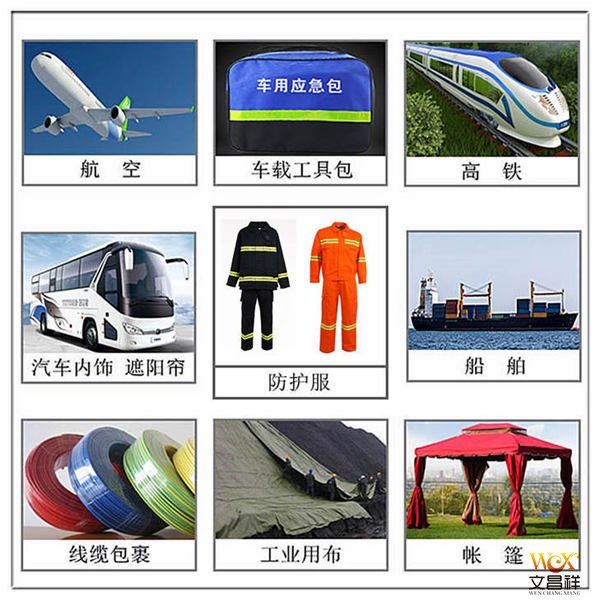

Flame-retardant fabrics: cotton, polyester, nylon, acrylic, aramid, viscose, asbestos, fiberglass, and flame-retardant synthetic plastics. It can also be blended, interwoven and other materials.

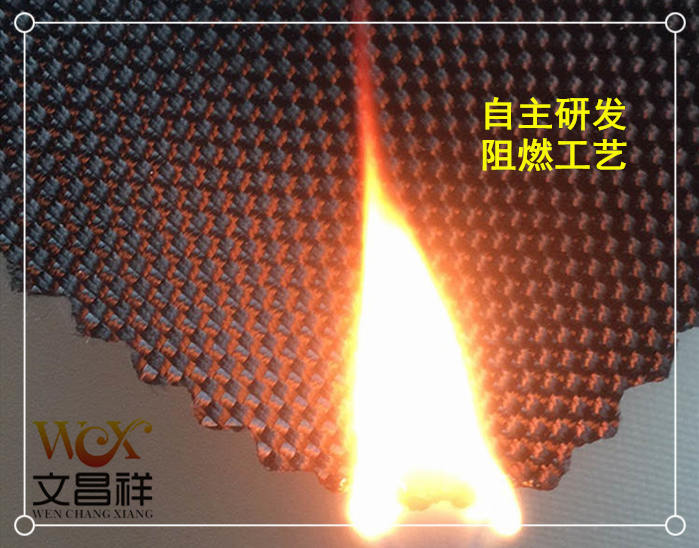

There are two main ways for textiles to achieve flame retardant functionality. These two ways give fabrics flame retardancy in different steps and produce different effects.

First, the flame retardant with flame retardant function is added to the fiber through polymer polymerization, blending, copolymerization, composite spinning, graft modification, etc., to make the fiber flame retardant. Second, the flame retardant is coated on the surface of the fabric or penetrated into the interior of the fabric using post-finishing methods.

Various fabrics can be treated with flame retardants, so the flame retardant process is closely related to the physical and chemical properties of the material. Even if the same flame retardant is used on fabrics of different materials, their flame retardant effects will be different. the difference.

Flame-retardant fabrics are becoming more and more widely used in public places such as large shopping malls, hotels, supermarkets, and cinemas, as well as in home decoration, lighting, and daily life, including during construction. It can be used to prevent sparks from flying and effectively ensure people’s safety.

Independently research and develop flame-retardant fabrics. According to different requirements of customers, the following specifications are available: 210D, 300D, 420D, 600D, 900D, 1200D, 1680D Oxford cloth, etc., with temporary flame-retardant fabrics. Effect, semi-durable flame retardant effect and durable flame retardant effect. It can also be equipped with waterproof, flame retardant, PVC/PU coating, silver coating, composite and other treatments according to customer needs. You can contact the online customer service on the web page, or You can leave a message and we will provide dedicated service to meet all your requirements.

</p