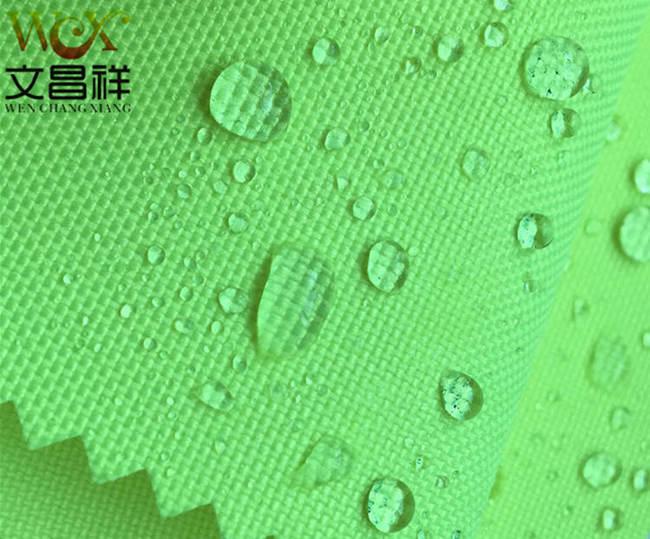

The process of waterproof Oxford cloth, the difference between wet and dry coating of Oxford cloth lies in the primer And the coating passes through the water tank, and its adhesive surface is solidified under the action of water. Other physical test standards are consistent with it. Wet coating mechanically fixes polyurethane and adhesive on the surface of the fabric, which is environmentally friendly. The adhesive surface can be white, silver, transparent, black, etc.

Wet coating process: the incoming fabric is inspected and passed—receiving the fabric—making it into a large roll—waterproofing—calendering—priming glue—passing the water trough—coating- –Water sink—drying—shaping—finished product inspection—packaging. After the waterproof Oxford cloth wet coating process is completed, the following physical properties must be tested: waterproofing, tearing strength, coating uniformity, rain, water pressure resistance, moisture permeability, and adhesive surface peeling fastness.

Waterproof Oxford cloth is widely used in sportswear, down jackets, rainproof parkas, jackets, tents, shoes and socks, curtains, bags, as well as ski shirts, mountaineering clothes, windbreakers, etc. with advanced waterproof and moisture-permeable functions. It can also be used in national defense, navigation, fishing, offshore oil wells, transportation and other fields. Waterproof coating series fabrics have multiple functions such as windproof, waterproof, and moisture permeability.

What are the specifications of Oxford cloth? Such as 1680D, 1200D, 900D, 600D, 420D, 300D, 210D, 150D and other Oxford cloth. Function classification of Oxford cloth: fire-retardant cloth, waterproof Oxford cloth, PVC Oxford cloth, PU Oxford cloth, camouflage Oxford cloth, fluorescent Oxford cloth, Printed Oxford cloth, composite Oxford cloth, etc.

</p