As people’s awareness of safety and prevention increases, flame-retardant Oxford fabrics are used in various fields around the world. Applications are becoming more widespread. Flame-retardant Oxford fabric is a fabric that can effectively prevent or slow down the spread of flames when in direct contact with flames or high-temperature objects, and carbonizes to form a flame-retardant isolation layer to protect the human body from harm. Normally, except for natural flame-retardant oxford fabrics such as aramid and molyk, most flame-retardant oxford fabrics are post-processed from ordinary fabrics with flame retardants added.

Flame retardant There are usually three types of flame retardant finishing agents: temporary flame retardant finishing agents, semi-durable flame retardant finishing agents and durable flame retardant finishing agents.

Temporary flame retardant finishing agents have the lowest cost and simple treatment methods, but they are not durable Washable, the flame retardant effect of the fabric disappears easily after washing, so it is suitable for fabrics that do not need to be washed.

Semi-durable flame retardant treatment agent. The treated fabric can withstand about 10 times of washing with warm water, but it is not resistant to high temperature soaping. The cost is higher than that of temporary flame retardant treatment agent. It is suitable for flame retardant fabrics that do not need frequent washing. Oxford cloth fabric used.

The fabric treated with durable flame retardant finishing agent can be washed up to 30 times The above are the most widely used flame retardant finishing agents in the flame retardant Oxford fabric industry.

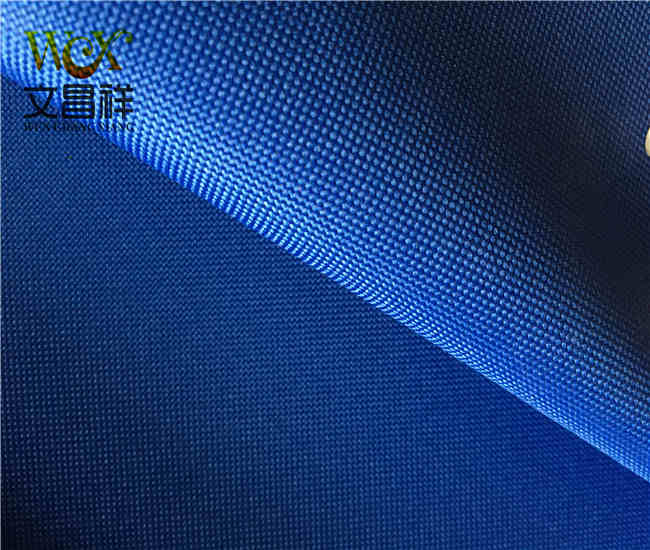

What are the specifications of Oxford cloth? Such as 1680D, 1200D, 900D, 600D, 420D, 300D, 210D, 150D and other Oxford cloth. Function classification of Oxford cloth: fire-retardant cloth, waterproof Oxford cloth, PVC Oxford cloth, PU Oxford cloth, camouflage Oxford cloth, fluorescent Oxford cloth, Printed Oxford cloth, composite Oxford cloth, etc.

</p