“D” is an expression of fineness of chemical fiber, a fineness index, referred to as denier. The larger the D value, the thicker the silk. If the silk is thick, it is logical that the cloth will be thicker. For example, the larger the number of 300D, 420D, 600D, 900D, and 1680D Oxford cloth, the thicker and wear-resistant the Oxford cloth is.

300D Oxford The cloth is woven from 300DX300D warp and weft yarns on a water-jet loom with a plain weave. The density is 16*25 (different densities and weights can be customized according to different needs), and the width is 150CM. After successively undergoing pre-shrinking, shaping, dyeing and a series of post-finishing processes, such as printing, coating, creasing and lamination, the product width is 146-148CM.

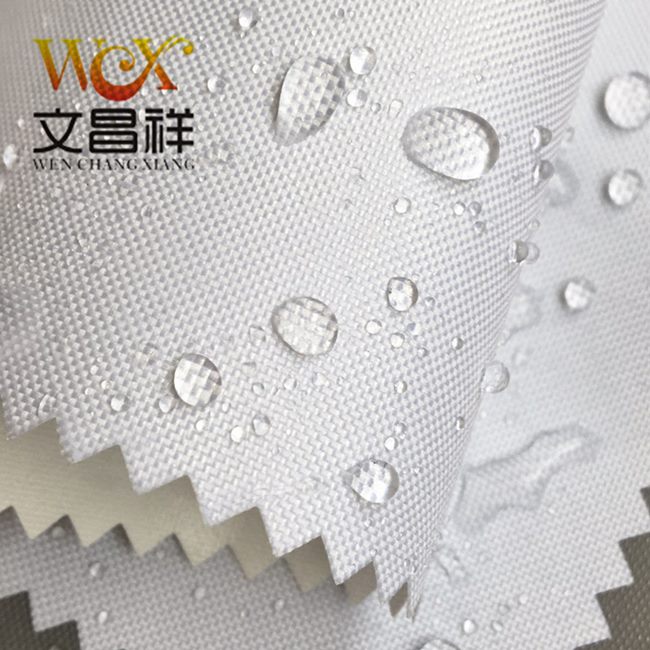

For outdoor backpack fabrics The waterproof characteristic of 300D Oxford cloth is usually due to the waterproof treatment in post-processing. The water-repellent treatment is actually a layer of special treatment covering the surface of the fabric. It is usually added when the finished fabric is finalized to obtain durable water-repellent properties. The advantage of using this treatment is that the surface layer does not absorb moisture, ensuring that the waterproof Oxford cloth can achieve good breathability.

300D waterproof Oxford cloth has the characteristics of soft hand, good firmness, high color fastness, strong three-dimensional effect, beautiful and durable, etc. It is mainly used to make bags, sports and leisure products, outdoor products, etc.

Specifications of Oxford cloth What? Such as 1680D, 1200D, 900D, 600D, 420D, 300D, 210D, 150D and other Oxford cloth. Function classification of Oxford cloth: fire-retardant cloth, waterproof Oxford cloth, PVC Oxford cloth, PU Oxford cloth, camouflage Oxford cloth, fluorescent Oxford cloth, Printed Oxford cloth, composite Oxford cloth, etc.

</p