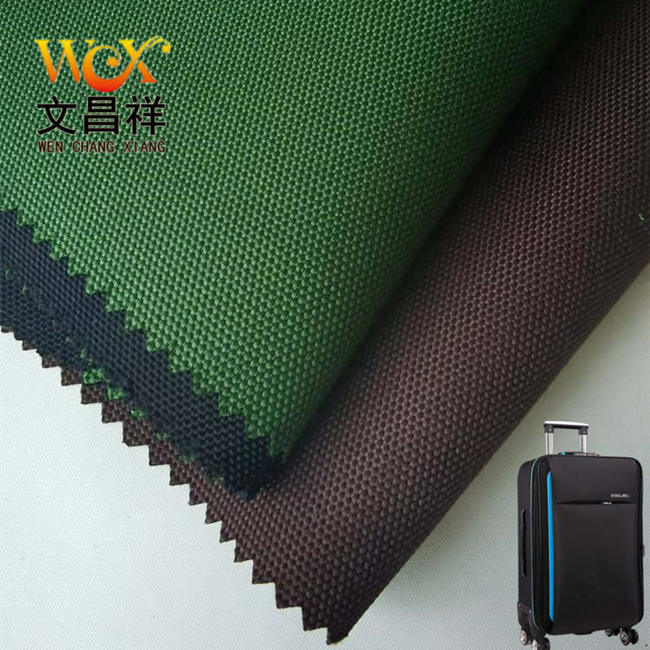

600D and 900D Oxford cloth are luggage materials that are widely used in the production of various types of travel bags and suitcases. The main difference between the two is their density and strength. 600D Oxford cloth has lower density and lighter weight, but is slightly inferior to 900D in strength. In comparison, 900D Oxford cloth is denser and heavier, but it also provides higher strength and durability. This makes 900D Oxford cloth more suitable for making durable travel bags and luggage that are often hit. However, this does not mean that 600D cannot achieve the same effect, but it may require more careful maintenance compared to 900D. No matter which material you choose, it’s important to properly maintain and care for your products during use to ensure they can stand up to daily beatings and long-term use.

Both Oxford fabrics can undergo a series of post-finishing processes to make the fabric functional, such as Waterproof The water pressure resistance can be customized from 1000mm to 10000mm. Choose a waterproof process according to your needs. The effect will amaze you! Commonly used in outdoor equipment, you don’t have to worry about rainy days. In addition to being waterproof, they can also be flame-retardant, coated, UV-resistant, etc. These different processes allow the two fabrics to be used in a wider range of applications, such as industry, agriculture, daily life, etc.

Oxford cloth and environmentally friendly recycled series specification classification: 1680D Oxford cloth, 1200D Oxford cloth, 900D Oxford cloth, 600D Oxford cloth, 420D Oxford cloth, 300D Oxford cloth, 210D Oxford cloth, 150D Oxford cloth, etc.; classified by function: flame retardant Oxford cloth, waterproof flame retardant cloth, silver-coated flame retardant cloth, pu waterproof Oxford cloth, PVC Oxford cloth, TPE, TPU, anti-UV , camouflage Oxford cloth, fluorescent Oxford cloth, composite cloth, etc. Please consult customer service for details. </p