New rolling mill

In order to improve the uniformity of the pad solution, printing and dyeing machinery manufacturers in various countries are committed to developing new rollers, especially Germany and Japan, which have made great progress in this regard.

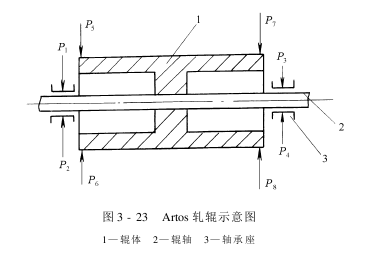

Figure 3 Shown at -23 is the Artos roller developed by the German Artos company. The lower roller is a normal roller, and the upper roller is the so-called Artos roller, which is a medium-solid roller with pressure at both ends. Eight pressure points are set on the roller body and both ends of the roller shaft of the Zhonggu roller. By adjusting these eight pressure parameters to adjust the pressure and deflection of the roll, the effect of improving the uniformity of the rolling fluid can be achieved. This type of roll is also effective when used on wide-width rolling mills. However, its structure is complex and its operation and maintenance are troublesome.

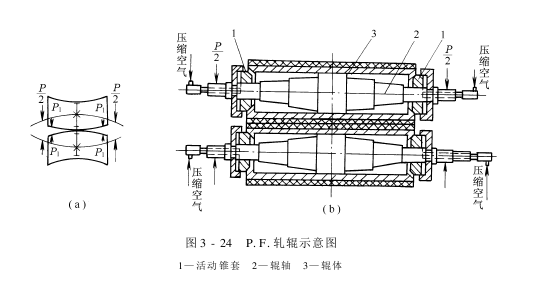

The P.F. roller shown in Figure 3-24 is made in Japan. The upper and lower rollers have the same structure. A pair of medium-solid rollers bends and deforms after being pressurized, resulting in a situation where the linear pressure is large in the middle and small at both ends, as shown in Figure 3-24(a). An additional pressure device is installed inside each end of the roller body, as shown in Figure 3-24(b). It consists of a tapered sleeve installed in the inner holes at both ends of the roller body and a tapered block that can slide axially on the roller shaft. The compressed air introduced from the center hole of the roller shaft head can make the tapered push block move axially into the roller body. The tapered surface presses against the inner surface of the tapered sleeve to generate a lateral additional pressure, which changes the deformation of the end of the roller body. By adjusting the pressure of compressed air, the additional pressure for lateral correction of deformation can be adjusted to suit the rolling pressure. The taper of the tapered push block and sleeve cannot be large, otherwise, the lateral correction will be small; but it cannot be too small, because self-locking occurs, generally about 10°.

Actually, The basic principle of this kind of roll is similar to that of the Artos roll. It uses the reverse torque applied to both ends of the roll body to balance the bending moment generated by the working pressure at both ends of the roll and reduce the deformation of the roll. However, the P.F. roller has a simple structure and is easy to operate and maintain.

Theoretically, these two types of rolls do not fundamentally solve the problem of rolling liquid uniformity, but only improve it. But judging from the actual results, it can basically meet the current process requirements.

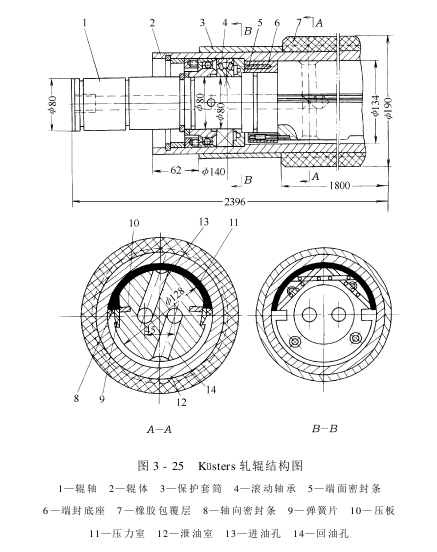

Based on the principle of adding fulcrums, the German Küsters company developed the world’s first uniform rolling mill in 1955. This kind of rolling mill achieves considerable uniformity of the rolling solution and is recognized as an ideal coloring rolling mill.

Generally, the outer wall of the roll of a rolling car is subject to a uniformly distributed load, and the fulcrums are at both ends of the roller shaft, so a certain deflection is produced.

If the number of fulcrums of the roller increases, the deflection will inevitably decrease; when the number of fulcrums increases to infinity, the deflection will become zero. According to this idea, liquid or gas with a certain pressure is passed into the inner cavity of the roller, and a uniform force (like an infinite fulcrum) is formed on the inner wall of the roller that is balanced with the load on the outer wall, and the deflection of the roller becomes zero.

Figure 3-25 is the structural diagram of the German Küsters roll. The roller body is installed on the bearing and rotates around the fixed roller shaft. The cavity between the roller shaft and the roller body is divided into two chambers by the end sealing strip and the axial sealing strip. The semi-annular cavity on one side of the rolling point is called the pressure chamber; the semi-annular cavity on the other side of the rolling point is called the drain chamber. Pressure oil enters the pressure chamber through the oil inlet hole on the shaft end. The oil that leaks into the oil drain chamber flows back to the oil tank through the oil return hole on the shaft.

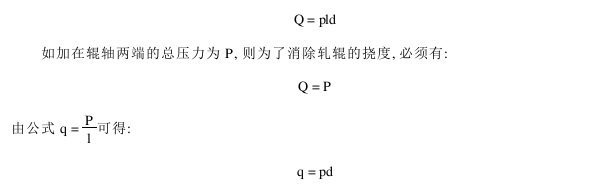

Suppose the inner diameter of the roller is d, the working amplitude is l, and the pressure of the oil entering the pressure chamber is p, then the total pressure on the inner wall of the roller is:

That is to say, the linear pressure of this kind of roll is only related to the inner diameter of the roll and the oil pressure of the pressure chamber, but has nothing to do with the working range. This provides a new theoretical basis for the design of various wide and extra wide rolling mills.

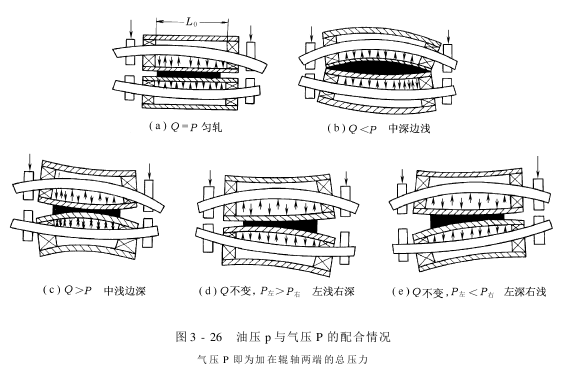

Küsters rollers can not only produce good even rolling effects, but also, by adjusting the inner cavity oil pressure p, the total pressure on the inner wall of the roller can be changed to achieve various uneven rolling effects to adapt to various extraordinary processes. requirements, as shown in Figure 3-26.

Küsters rolling The use and maintenance of the car is more complicated than that of a general rolling car. The following points must be paid attention to:

(1) The hydraulic system and the pneumatic system are interlocked when driving. When connecting to an external motor circuit, the pressure relay in the control box should be connected according to the interlocking requirements.

(2) When the machine is running empty and needs to be pressurized, water should be flushed between the rolls to prevent dry friction and heat generation.

(3) Hydraulic oil should be selected appropriately. Usually, use No. 70 engine oil in winter and No. 90 engine oil in summer, and use water circulation for cooling.

(4) The internal and external pressures should have a certain range and should not differ too much.

The successful development of Küsters rollers is a major breakthrough in the history of roller manufacturing. At present, it is not only used in pad dyeing, but also widely used in finishing and high-efficiency padding.

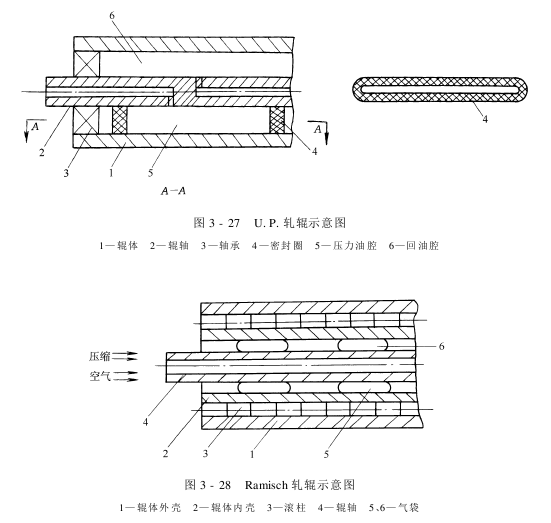

Japan has developed a similar uniform roll – U.P. roll, based on the principle of the German Küsters roll.�As shown in Figure 3-27. The sealing member of this roller is an oblong sealing ring, which has a simple structure and is easy to manufacture. However, due to the shrinkage of the pressure chamber, under the same working conditions, the pressure of the U.P. roller is about 3 times greater than that of the Küsters roller, seriously reducing the service life of the seal.

The sealing of hydraulic uniform rolls is always relative, while leakage is absolute. As working hours increase, leakage will continue to worsen. The total leakage is less than 70% of the oil supply of the oil pump, and the roller can still work normally. However, if it exceeds this number, it must be repaired.

German Ramisch Company has created an air bag type uniform roll, as shown in Figure 3-28. This kind of roller not only solves the contamination problem caused by oil leakage of the hydraulic uniform roller, but also overcomes the problem of difficult sealing of the hydraulic roller to a certain extent. The roller body of this kind of roller is composed of two layers of relatively rotatable steel cylinders, with multiple rows of rollers installed in between. The entire roller body is like a thick and long bearing. The inner layer is fixedly mounted on the roller shaft, and the outer layer is fixedly mounted on the roller shaft. Can rotate freely. In the cavity between the inner layer and the roller, 8 air bags are installed, distributed on both sides of the roller, 6 of which are on the pressure side and 2 on the opposite side. These air bags are directly connected to the air pump through pipes and air valves. As long as the air valve is operated, the pressure of each air bag can be adjusted to coordinate with the rolling pressure at both ends of the roller, thereby achieving an even rolling effect. In addition, through different combinations of each air bag pressure and rolling pressure, different rolling effects can be obtained.

Therefore, This kind of roller is very sensitive and easy to operate. It has good sealing and no contamination. However, the manufacturing process requirements for the inner and outer layers are relatively high, and the price of the rolling mill is also high.

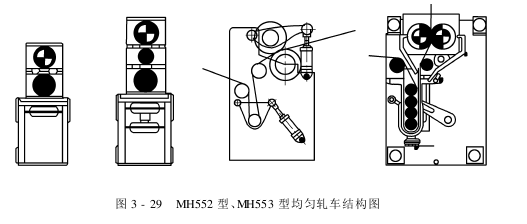

Domestic production The MH552 and MH553 uniform rolling mills are shown in Figure 3-29. The machine consists of left and right wall panels, control panel, roller, control box, air bag, cylinder, etc. The wall panel material is cast iron, and the characteristic of the roller is that the shell rotates but the core shaft is fixed, which requires good sealing performance in the radial direction and axial direction at both ends. The roll material is a seamless steel pipe covered with nitrile rubber, the outer diameter of the roll is 190mm, and the rolling groove adopts a cylinder that can be raised and lowered through a lever. The rolling groove liquid level control uses air blowing automatic control device. Four cyanoacrylate rubber rollers are arranged in a stationary manner in the rolling tank, so that the fabric can obtain multiple dipping and multi-padding effects in the rolling tank.

AAASDFERHYTJTI

Extendedreading:https://www.alltextile.cn/product/product-32-135.html

Extendedreading:

Extendedreading:

Extendedreading:

Extendedreading:

Extendedreading:

Extendedreading:

ExtendedReading:

Extendedreading:

Extendedread