Zigzag ginning theory Movement of sub-laps

The ginning process requires ginning the long fibers on the cotton without damaging the natural physical properties of the fibers. According to the ginning mechanism, to achieve this requirement, cotton seeds and long fibers must be subjected to external forces in different directions. The middle box of the sawtooth gin creates the conditions for it. The geometry of the middle box allows the cotton to form a roll. The position of the saw blade roller in the middle box is used to make the saw teeth pull the cotton fibers while pulling the cotton into a roll. The acting moment is generated to make the cotton roll rotate and relax. It is precisely because of the rotation of the cotton roll that the saw teeth can pull the fibers in a balanced and efficient manner; at the same time, the cotton cotton with clean fibers can be smoothly discharged. Because there are differences in the rotation speed and direction of the sub-roll and the saw blade drum, especially at the working points of the ginning rib rows, the mechanical conditions of ginning can be met.

(1) The formation process of sub-cotton rolls

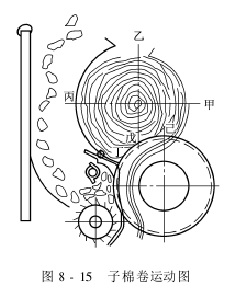

Before ginning, put a certain amount of sub-cotton in the middle box so that the sub-cotton rolls can be formed quickly after starting the machine. When ginning, the cotton in the front box is pulled by the sawtooth hook and enters the middle box through the upper gap of the rib row of the resistance shell, and is distributed on the outer surface of the cotton roll, as shown in Figure 8-15.

Congmian The sub-comb reaches the arc length of the saw blade at the working point of the embossed rib row, and the saw teeth continue to pull the cotton fibers. The cotton pulled by the saw teeth is loosened with the saw blade, but the cotton is also restrained by the cotton roll, so some of the fibers in the fiber bundles hooked by the saw teeth are pulled off the cotton. At the working point of the embossed rib row, the sawtooth pulls the cotton fibers into the rib gap, and most of the fibers and cotton are separated. The sub-cotton that has been pulled out of some fibers is blocked by the embossed ribs and remains in the middle box. Since the subsequent saw teeth continuously leave the cotton with part of the fiber pulled out above the working point, the cotton here is squeezed very tightly and squeezes upward along the surface of the ginned rib row, pushing the cotton in front to move upward. As a result, the cotton in area A falls to area B, and then to areas C and D, forming the outer layer of cotton rolls. When the cotton is leisurely near the cotton comb, it meets the newly entered cotton in the middle box, and is pulled into its own area by the sawtooth hook again. The cotton with clean fibers is discharged from the machine near the cotton comb. This process goes over and over, constantly taking away fibers and discarding cotton seeds, and constantly hooking in cotton seeds to replenish them. The cotton fibers in the middle box are always in a stable rolled state, constantly resting along the inner wall of the middle box.

Cotton roll is a mixture of cotton, wool, free fiber, cotton, etc. When the outer layer of the cotton roll rotates, the friction between the layers pulls the inner layer of cotton along with it. Casual outer layer together. In this way, the entire sub-cotton roll rotates around a certain center, which also creates conditions for the cotton fibers to be smoothly peeled off from the sub-cotton.

(2) Basic conditions for the leisure of sub-cotton rolls

The normal operation of sub-cotton rolls is an indispensable condition to ensure good ginning status. In order to ensure that the saw teeth can pull the cotton fibers continuously and evenly, the following conditions must be met for the normal operation of the cotton roll:

(1) The cotton roll should have a certain density. Only when a sub-cotton roll has a certain degree of compactness can each single particle of cotton squeeze each other appropriately, forming a certain amount of friction to transmit torque, causing the inner and outer layers of the sub-cotton roll to pull each other to form an overall fit.

(2) The traction torque of the saw teeth on the cotton roll must be greater than the frictional resistance torque of the working box wall on the cotton roll. In order to increase the traction torque of the saw teeth on the cotton roll, the following measures can be taken:

① Raise the saw blade drum and increase the number of working teeth of the saw blade in the working box.

②Keep the sharpness of the saw teeth; keep the teeth continuous and do not reverse the teeth; the brush cotton should be clean.

③Appropriately reduce the pressure angle.

In order to reduce the frictional resistance moment of the working box wall to the cotton roll, the following measures can be taken:

① Improve the cleanliness of the inner wall of the working box and the surface of the embossed ribs, especially the upper heel fixation of the embossed ribs , should be flat and completely smooth.

② Appropriately increase the gap above the working point of the embossed rib row, expand the diameter of the top hole, and improve the cleanliness of the side and top holes of the embossed rib working point and above.

③ Install and adjust the cotton comb correctly to prevent the comb from being misaligned and blocking the row.

④After starting the machine for a certain period of time, the cotton roll should be replaced or cleaned. Because there are often impurities in the center of the cotton roll, they cannot be pulled out by the saw teeth, and they are not easily discharged with the cotton. As the finishing time is extended, there will be more and more impurities. Some of these impurities will block the ginned rib rows. The gap causes the sub-roll to stop rotating.

⑤ Control the density of the sub-roll to prevent the sub-roll from being too tight, causing a sharp increase in frictional torque and affecting the operation of the sub-roll.

(3) The distance between saw blades should not be too large, generally within 20mm. If the blade distance is too large, it is difficult for the cotton between the saw blades to obtain traction, and it is difficult to relax with the cotton roll.

(3) Composition of sub-cotton rolls

The fibers on the single-grain cotton cannot be completely pulled through one sawtooth hook, that is, the rolling and peeling process of the single-grain cotton is completed within a certain time interval.Under other working conditions, the density of cotton rolls must increase. Within a certain range, the density of the sub-cotton roll increases, the pressure of the sub-cotton roll on the saw blade drum also increases, the hooking and traction effect of the saw teeth on the sub-cotton roll is also strengthened, and the speed of the sub-cotton roll increases. However, if the sub-roll is too tight, the resistance torque generated by the working box wall against the loose roll will increase rapidly, causing the sub-roll to slow down or even stop.

2. Cotton comb position

When only changing the cotton comb position without changing other working conditions, the cotton comb is raised to the level, so that the bottom of the cotton roll is approximately round, and the cotton in area D is The roll density increases, thus affecting the discharge of cotton seeds. By prolonging the stay time of the cotton seeds in the working box, the density of the cotton seeds will increase and the leisure speed will be accelerated. On the contrary, the cotton comb tilts downward, the lower part of the cotton roll expands into a cone shape, the row is unobstructed, the density of the cotton roll decreases, and the leisure speed also decreases.

3. Saw blade drum speed and gin productivity

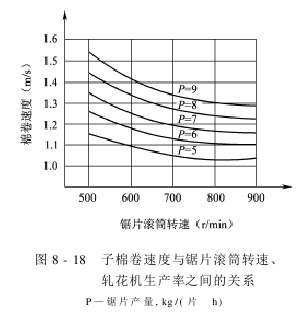

The relationship between the leisure speed of sub-rolls, saw blade drum speed and gin productivity is shown in Figure 8-18. Under the same productivity conditions, increasing the rotation speed of the saw blade drum will make the sub-cotton roll looser and reduce the leisure speed; under the same conditions of the saw blade drum rotation speed, increasing the productivity of the gin will make the sub-cotton roll tighter and speed up the relaxation speed. .

4. The position of the ginned rib row

Changes in the position of the ginned rib row will cause the following changes:

(1) R 1 (the distance from the center of the cotton lap to the rib) changes, which will cause the Changes in lap shape and circumferential density;

(2) Changes in the width of the row, thus affecting the speed of the row;

(3) Changes in the relative position of the embossed rib row and the saw blade drum, thus Change the force exerted by the saw teeth on the cotton roll at the working point.

AAAWQ32RDRGFJ