Cotton management, cotton cleaning machinery

(3) Seed cotton cleaning machine

Looking at various sesame cleaning equipment, the cleaning components mainly include spike rollers, rack rollers, and saw blade rollers. Regardless of the type of roller, it must be combined with surrounding components to complete cleaning. In order to improve the efficiency of cleaning, several different forms of cleaning equipment can be used at the same time to clean the debris.

1. Spiked drum cleaning machine

Spiked drum cleaning machine, also known as spiked drum cleaning machine or spiked cleaning machine. It was used earlier and was used to sort hand-picked cotton. Now it is used in conjunction with other equipment to sort machine-picked cotton and manual quick-picking cotton.

The spiked roller cleaning component consists of a spiked roller and a lower arc-shaped screen, which uses the principle of screening to separate impurities and cotton. The cotton enters between the spike roller and the dust removal net. Under the continuous impact of the spikes, it rolls, collides and shakes along the surface of the dust removal net, causing the dust and debris in the cotton fibers to separate and be discharged from the dust removal mesh. At the same time, the seed cotton is also opened.

The factors that affect the efficiency of nail roller cleaning are:

(1) Characteristics of sub-cotton: good quality, low moisture content of sub-cotton, cotton fiber elasticity, easy to separate impurities, high impurity cleaning efficiency . On the contrary, sub-cotton fibers with poor quality and high moisture content have low elasticity, impurities are easily entangled with the fibers, are difficult to separate, and have low impurity cleaning efficiency.

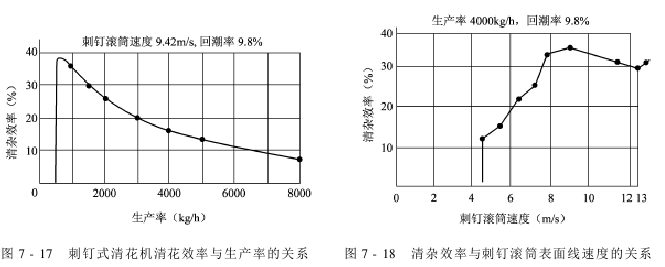

(2) Productivity of the cleaning machine: Under certain conditions, the greater the quantity of cotton to be cleaned, the worse the cleaning efficiency will be. Therefore, the technical specifications of the cleaning machine should be determined based on the amount of cotton treated and the impurity content. The relationship between the impurity cleaning efficiency and productivity of the spike cleaning machine is shown in Figure 7-17.

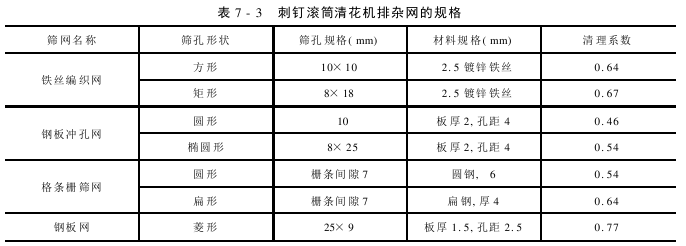

(3 )Linear speed of the spikes: The linear speed of the surface of the spike roller directly affects the effect of cleaning and loosening cotton. Within a certain range, increasing the surface linear speed of the spike drum is an effective measure to improve productivity and improve the effect of cleaning and loosening cotton. However, the surface linear speed of the spike roller is too high, which can easily break cotton flaps and impurities and increase energy consumption. Therefore, the surface linear speed of the spike roller should be considered comprehensively in combination with the properties of the cotton. Generally, when sorting normal mature cotton, the surface linear speed of the spike roller is set to 8~9m/s. At this time, the impurity removal rate reaches 35%. When the surface linear speed of the spike roller exceeds 11m/s, the cotton will be crushed. , damage the fibers and increase defects in the lint. If the cotton with poor maturity is sorted, the surface linear speed value of the spike roller should be set to 5~6m/s. The relationship between the impurity cleaning efficiency and the surface linear speed of the spike drum is shown in Figure 7-18.

For multi-drum cleaning machines, in order to prevent the cotton clumps from clogging and ensure the normal operation of the cleaning machine, the surface linear speed of the spike drum should increase one by one as the cotton is cleaned, and the increase rate should be greater than 3%.

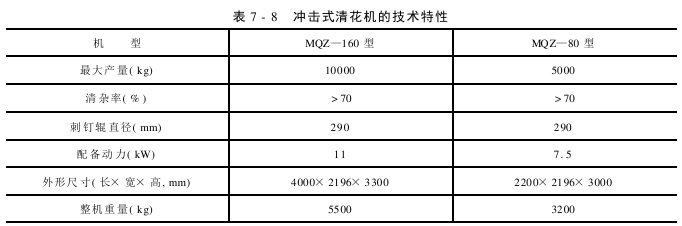

(4) The structural form of the screen and its cleanliness: The impurity discharge nets of the spike drum cleaning machine include wire braided nets, steel plate punched nets, grid screens and steel plate meshes. The impurity removal efficiency of the impurity removal screen is related to the effective area of the screen holes, the arrangement of the screen holes, the shape of the screen holes and the surface area of the screen.

The ratio of the effective area of the screen holes (S0) and the surface area of the screen (S t) is called the cleaning coefficient (μ) of the screen, that is:

μ=S0 /St

The screen hole specifications and corresponding cleaning coefficients of various impurity removal screens are shown in Table 7-3.

Generally , the greater the cleaning coefficient of the screen, the higher the cleaning efficiency of the screen. As can be seen from Table 7-3, the cleaning coefficient of steel plate punching mesh is small, while the cleaning coefficient of steel plate mesh is large. The cleaning coefficient of the finished pipe grating is smaller than that of the iron wire mesh, but practice has proven that its impurity cleaning effect is better than that of the iron wire mesh. In addition to being able to separate small impurities such as broken cotton leaves and sand, it can also separate infertile and stiff valves. The main reason for the slightly larger impurities is that the impurities and stiff flaps are easily discharged from the strip holes. The cleaning coefficient of expanded steel mesh is large, and theoretically speaking, its impurity cleaning effect should be good. However, because the surface of expanded steel mesh is uneven and it is easy to hook fibers, it is rarely used in actual production.

(5) The distance between the tip of the spike and the surface of the impurity removal screen: This is the effective space for the cotton cleaning process, which is called the “cleaning aisle”. You want to ensure that this aisle is smooth. The requirements are: the spikes are moderately distributed on the surface of the drum; the distance between the spikes and the mesh surface should be determined according to the quality of the sub-cotton and the size of the cotton flaps. The size of this spacing should be such that the cotton can roll forward on the mesh surface, generally 18 to 25 mm. For multi-roller blowroom machines, this gap should gradually increase from the cotton inlet to the cotton outlet along with the loosening of the cotton. At the cotton outlet, the gap should be large rather than small.

The impurity removal screen should match the spike roller, and its shape is generally arc-shaped. The arc of the impurity removal screen corresponds to the central angle φ of the spike drum (Figure 7-19), which is a relatively important parameter. If the value is too large, the cotton will easily return with the spikes and cause repeated blows, resulting in defects such as neps and cords. On the contrary, straight connecting sections will inevitably appear between the impurity removal screens, and the cotton will easily stay here. Causes clogging. Secondly, it also reduces the scope of cooperation between the spikes and the impurity removal screen, affecting the impurity removal efficiency. Generally, φ should be controlled between 110° and 115°.

<img src="https://www.zuranmianliao.cn/UploadThespacingbetweenthegridsis10mm,thespacingbetweenthesawteethandthewirebrushstripsis0~5mm,andthespacingbetweenthesawteethandtheadjustabledebrisremovalplateis5mm.

ThestructureoftheMQZseriesimpactblowerisshowninFigure7-25.Itconsistsofcottonfeeding,looseningandimpurityremoval,wasterecyclingandotherparts.

Feed cotton It is partly composed of cotton feeding roller, soft waste recovery roller, cotton holding bucket and other parts. The function of this part is to evenly feed the cotton into the loosening and impurity removal part, and at the same time, the soft trash recovery roller wraps around the soft and special trash in the cotton to achieve the purpose of separating the soft and special trash.

The loosening and impurity removal part consists of 5 spike rollers and 5 saw blade rollers. Five spike rollers are arranged in parallel at the top, and five saw blade rollers are arranged in parallel at the bottom. They are inclined at 45° to the horizontal plane. The saw blade drum is composed of a saw blade and a spacer ring that are alternately sleeved on a shaft.

The waste recycling part consists of wire brush strips, U-shaped sawtooth rollers, i.e. lower recovery rollers, impurity removal adjustment plates, adjustable grids, middle recovery rollers, upper recovery rollers, impurity removal spirals, etc. Its function is to recover single particles of cotton, small flower heads and stiff cotton that are discharged from the loose cotton impurity removal part.

The technical characteristics of the MQZ series impact blower are shown in Table 7-8.

AAAFGBHGYUTKU