Quick collection of useful information! 20 common textile fabric defect terms

1, crotch defect (Barre)

For knitted fabrics, this defect is characterized by some uneven patterns that usually appear in the fabric courses or in the transverse direction of the fabric. Uneven spinning threads, uneven spinning thread tension, and spinning threads with different dye affinities may be the reasons for this.

2. Bias (reference weft bias)

For woven fabrics, this defect refers to the dimensional deviation of the weft and warp yarns; for knitted fabrics, this refers to the fabric course and fabric wale Where dimensional skew occurs.

3. Birdseye Defect

For knitted fabrics, this situation refers to the occasional and irregular tuck weave that is opposite to the fabric design.

4. Bow

For woven fabrics, this situation means that the weft yarns are located in the width direction of the fabric in an arc; for knitted fabrics, this situation means that the stitch courses are located in an arc. The thread pattern is in the width direction of the fabric.

5. Broken End

This defect refers to the place where the warp yarn has been broken and repaired. Its common feature is that the broken ends can be seen in the fabric.

6. Broken Color Pattern

For woven fabrics, this condition refers to discontinuities in the pattern, errors in drawing colored patterns with loom threads, or damage to the loom when weft threads break. Improper resetting of the image filling chain after repairs can cause this defect; in the case of knitted fabrics, this is caused by an incorrect shuttle change.

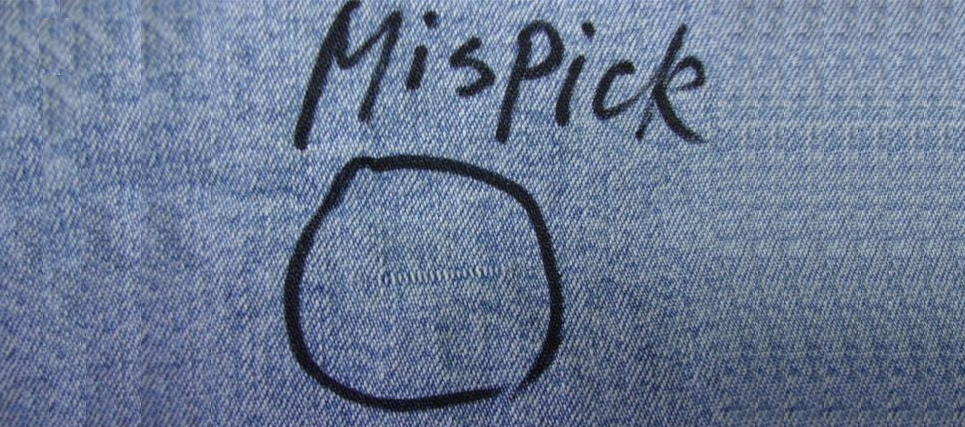

7. Broken pick

This is a condition where the weft is missing over part of the width of the fabric due to weft breakage.

8. Burl mark

This is a deformation caused by an excess of certain substances, including slubs, waste, and loose yarn that are being removed with repair tools.

9. Buttonhole selvage

This is a fabric selvage defect caused by excess tension built up on the loom shuttle before the weft is replaced. This tension tends to restrict the selvedge weft from falling off and interlacing properly, creating an imperfection similar to a buttonhole.

10. Chafed Yarn

This defect refers to the frayed spinning yarn. After the spinning yarn is worn, the fiber will lose its sense of direction and the spinning yarn will be distorted. This defect affects the colorability of the yarn and often results in radial stripes or weft streaks.

11. Chopped Filling

This defect refers to an imbalance in the weft direction and is characterized by the presence of a distinct or uniform pattern caused by the eccentric behavior of the drawing roller.

12. Clip mark

This defect is an area of fabric that has not been dyed. This defect is caused by small metal clips that are clamped to the edge of the fabric. These small clips are used to prevent or Used to correct fabric selvedge folding during coloring.

13. Coarse End

This situation means that the diameter of one warp yarn is significantly larger than the diameter of the normal warp yarn of the fabric.

14. Coarse Pick

This situation means that the diameter of one weft yarn is significantly larger than the diameter of the normal weft yarn of the fabric.

15. Coarse Yarn

This situation means that the diameter of one yarn is significantly larger than the diameter of the normal yarn of the fabric.

16. Cockled Fabric

In the case of knitted fabrics, these defects are wrinkles, wrinkles, or bulges that do not lie flat on the cutting table. The reason for this phenomenon may be due to the irregular twisting of the spinning yarn, the uneven tension of the spinning yarn during the knitting process, or the reaction of the spinning yarn in the fabric during the finishing process. The degree is uneven.

17. Cockled Yarn

This situation refers to a situation where some fibers in a spun yarn appear to be very curled and the direction of the fibers cannot be distinguished. The reason for this situation is that some spinning fibers are too long relative to the drawing roller, causing the fiber to be clamped by the following drawing roller before the previous drawing roller loosens the fiber. This will cause the fibers to break and curl. Twisted yarn looks like tiny twists in the fabric.

18. Color Fly (Color Fly)

This situation refers to the appearance of fiber impurities of different colors in spinning yarn or fabrics.

19. Color Out (Color Out)

During the printing process, if the color paste in the storage tank is almost used up, it will cause blank spots in the printing pattern.

20. Compactor Crease

For knitted fabrics, this defect refers to hard creases caused by wrinkles in the fabric during the shrinkage control and stabilization process.

——Professional functional fabric supply and application comprehensive service provider. The company has strong scientific and technological research and development capabilities, advanced production and inspection methods, and has self-operated import and export rights. It is also an ISO9001-2008 and ISO4001-2004 certified enterprise. The main products include: antistatic series, high temperature resistant and fireproof series, fireproof series, oil and water repellent and three-proof series, acid and alkali resistant series, general workwear fabrics and accessories, etc. Involving metallurgy, fire protection, petroleum, chemical industry, machinery, medical and other industries. After decades of hard work, market-oriented, innovation-driven, quality-based survival, we have developed and grown. Technology provides you with a full range of solutions and complete products and services.

AAAVBJYTUJGHNH

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA