The printing and dyeing factory is still in the throes of production shutdown and rectification, the environmental protection tax is coming, and dyeing costs are about to rise!

2016In December 2016, the Standing Committee of the Twelfth National People’s Congress held the second The “Environmental Protection Tax Law” was voted at the 15th meeting. As a separate tax law of our country to promote the construction of ecological civilization, the “Environmental Protection Tax Law” will be implemented on January 1, 2018. After the environmental protection tax is levied, it is estimated that the annual environmental protection tax collection scale will reach 50 billion yuan.

On June 26, the Ministry of Finance, the State Administration of Taxation, and the Ministry of Environmental Protection drafted the “Regulations on the Implementation of the Environmental Protection Tax Law of the People’s Republic of China” (Draft for Comments, hereinafter referred to as the Regulations) and publicly solicited opinions from the public.

The regulations announced this time include taxpayers, tax objects, tax calculation basis, tax exemptions, tax collection and management of environmental protection tax. An explanation was given and the terms contained therein were stipulated in detail. The public can submit comments through the Ministry of Finance website or by mailing letters before July 26.

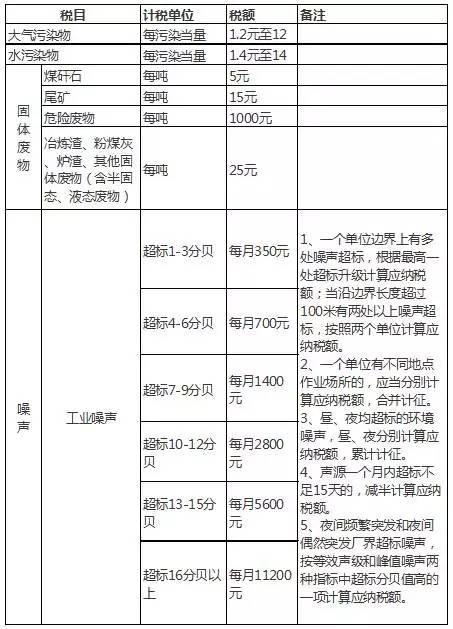

It is reported that the environmental protection tax is levied this time. The objects and scope of the tax are basically the same as the current sewage charges. It is clear that the tax scope covers air, water, solids, noise and other pollutants that are directly discharged into the environment.

The tax on air pollutants is 1.2-12 yuan per pollution equivalent;

Water pollutant tax is 1.4-14 yuan per pollution equivalent;

Based on different types of solid waste, the tax is 5-1,000 yuan per ton;

Based on the number of decibels that exceed the standard, the tax amount is 350-11,200 yuan per month.

Environmental Protection Tax Items and Amounts

In addition, in order to prevent pollutant-discharging enterprises from thinking that they can discharge wantonly after paying taxes, the Environmental Protection Tax Law clarifies that enterprises, institutions and other production operators that directly discharge taxable pollutants into the environment will not pay taxes in accordance with the provisions of this law. In addition to paying taxes on environmental protection, they should be held responsible for the damage caused in accordance with the law.

Major pollutant emissions from fabric printing and dyeing enterprises

1. The biggest hazard is wastewater

According to statistics, the wastewater discharge from the fabric printing and dyeing industry accounts for 7.5% of the national industrial wastewater discharge, ranking fifth in the national industrial industry, with a total volume of 1.413 billion tons/year. Among them, printing and dyeing wastewater is the main source of pollution in the fabric industry, with an annual discharge of approximately 1.13 billion tons (accounting for 80% of the wastewater in the fabric printing and dyeing industry) and 6% of the national industrial wastewater discharge. According to estimates, printing and dyeing plants produce approximately 200 tons of wastewater for every 10,000m of fabric processed.

2. Sewage

The traditional printing and dyeing finishing process will produce a large amount of toxic sewage. Some toxic dyes or finishing auxiliaries in the wastewater after finishing are attached to the fabric, which has a direct impact on human health. For example, azo dyes, formaldehyde, fluorescent brighteners and softeners are allergenic; polyvinyl alcohol and polypropylene slurries are not easily biodegradable; chlorine-containing bleaches are seriously polluted; some aromatic amine dyes are carcinogenic; dyes contain Harmful heavy metals; various finishing agents and printing and dyeing auxiliaries containing formaldehyde are toxic to the human body.

3. Air pollution

The waste gas in the fabric industry mainly comes from about 20,000 boilers in the industry. The total steam capacity of these boilers is about 60,000 tons. About 85% of the total boilers meet the smoke and dust emission standards. The vast majority of these boilers use coal (including some raw coal) as fuel. These coals contain a certain amount of sulfur and emit a large amount of combustion exhaust gas, sulfur dioxide and smoke during the combustion process, polluting the environment. Another major source of fabric exhaust emissions comes from the fabric production process. For example, in the production process of viscose fiber, a large amount of carbon disulfide and hydrogen sulfide are used as synthetic raw materials. Due to technological reasons and incomplete process control, some waste gas emissions are directly caused.

4. Noise pollution

Noise pollution is one of the more serious problems currently existing in the fabric industry, especially the cotton textile industry. Due to the extensive use of shuttle looms in cotton textile mills, the noise in the factory reaches 90~106dB, and The maximum acceptable value of noise for the human ear is only 85dB. To our countryThe actual detection of noise in cotton textile mill workshops by region shows that the average environmental noise in cloth workshops is 100 to 105dB.

According to analysis by industry insiders: Taking a medium-sized fabric printing and dyeing enterprise with an annual output value of 50 million yuan as an example:

The amount of air pollutant tax that needs to be paid every year is about 60,000 to 120,000 yuan in total;

The amount of water pollutant tax that needs to be paid is about 80,000 to 150,000 yuan in total;

You need to pay a tax on sawdust, dust, chemical waste, and other solid waste, which totals about 150,000 to 300,000 yuan;

The total amount of noise tax that needs to be paid is about 5,000-20,000 yuan per month.

In summary, the annual environmental protection tax for a medium-sized fabric printing and dyeing manufacturer should be between 300,000 and 700,000 yuan.

It can be seen that after the official implementation of the Environmental Protection Tax Law on January 1, 2018, the environmental protection costs of fabric printing and dyeing enterprises will be greatly increased.

AAAVEGTRHYTJ

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA