Characteristics of anti-static fabrics

How is static electricity generated

Cloth materials, especially synthetic fibers with low moisture absorption properties such as polyester, acrylic, and chlorine fiber, generally have high specific resistance. Therefore, during the fabric finishing process, static electricity is generated due to the close contact and friction between fibers and fibers or between fibers and machine parts, resulting in hairy slivers, increased hairiness in spinning yarns, poor package formation, fiber sticking to machine parts, and spinning yarns. Increased thread breakage, and the formation of scattered stripes on the cloth surface.

Static electricity problems and related measures

After the work clothes are charged, they will absorb a large amount of dust and easily become contaminated. In addition, the work clothes and the human body, work clothes and work clothes will also become entangled or generate sparks. Therefore, static interference affects the smooth progress of finishing, affects the quality of products and the wearing performance of fabrics. When the static electricity phenomenon is severe, the static voltage can reach several thousand volts, which can cause sparks due to discharge and cause fires, causing serious consequences. Anti-static fabric is a fabric that has been treated with anti-static finishing. After washing 100 times in an environment with a temperature of 20±5°C and a humidity of 30-40%, the average surface charge density of the anti-static fabric is ≤7.0 μc/m2. The coloring requirement for anti-static fabrics is light silk finish and no sanding. Please control the oxygen bleach at 80% of the dosage.

Finishing methods and applications of anti-static fabrics

There are usually several finishing methods for anti-static fabrics: first, the fabric is finished with an antistatic finishing agent; second, fiber grafting modification with the purpose of improving the moisture absorption of the fabric, Blended chemical fiber fabrics and interweaving of hydrophilic fibers; third, blended chemical fiber fabrics or inlaid conductive fibers; the mechanisms of the first two methods are to increase the moisture regain of the fabric, reduce the insulation, and accelerate electrostatic leakage. Therefore, if the finishing effect is not durable or not significant in a dry environment or after multiple cleanings, it is usually used on general workwear fabrics. Only the third method can permanently and efficiently solve the static problem of fabrics, so it is widely used in the production of anti-static workwear. The fabric is finished with an antistatic finishing agent. The types of anti-static fabrics include: anti-static silk (conductive silk) and anti-static ultra-clean fabrics, anti-static tc fabrics, anti-static tr fabrics, anti-static cvc fabrics, anti-static Cotton fabrics, etc.

The application of conductive fibers in antistatic products and related standard issues

It is worth mentioning that organic conductive fibers play an effective role in removing static electricity from workwear fabrics and general civilian fabrics. However, compared with conventional fabrics, fabrics containing conductive fibers The accuracy and attention to the method of testing the electrostatic properties of the product deteriorated significantly. Choosing reasonable testing methods and correctly evaluating the electrostatic properties of conductive fiber-containing fabrics are basic work necessary to conduct in-depth research on the finishing technology of organic conductive fibers, the production process of conductive fiber-containing fabrics, and to guide the rational application of such fabrics. We analyze the adaptability of my country’s current relevant test method standards to the antistatic performance testing of fabrics containing conductive fibers.

Practical application of antistatic principle

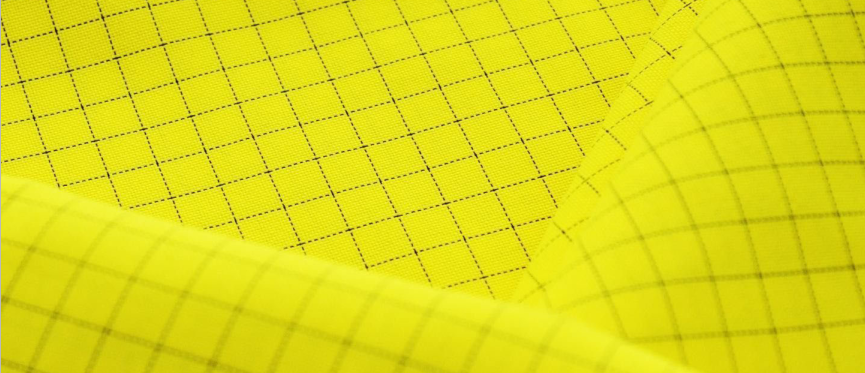

Work clothes made of anti-static fabrics mostly use stainless steel fiber, sub-conductive fiber, anti-static synthetic fiber and polyester-cotton blended chemical fiber fabric or blended fabric, which can automatically discharge corona discharge or leakage discharge. Removes static electricity from clothing and human body while providing hats, socks, and shoes that remove static electricity. Among them, anti-static work clothes can prevent the accumulation of static electricity in clothing. Work clothes sewn from anti-static fabrics. Anti-static fabrics can prevent the accumulation of static electricity in clothing. When fabrics are made, conductive fibers are mixed into the fabric at roughly intervals or evenly.

AAAFSGRETEGSDFW

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA