UV protection fabric technology and principles

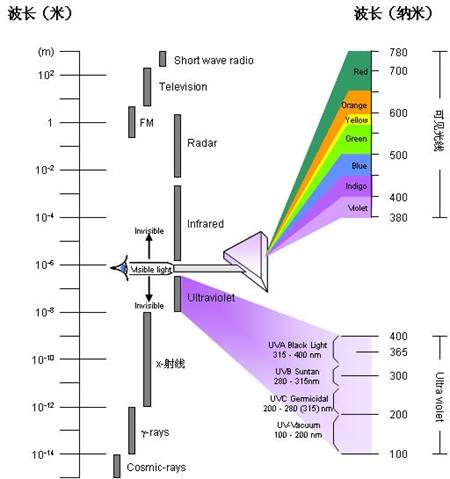

Ultraviolet rays are a type of radiation with a wavelength of 400 to 100nm. Appropriate amount of ultraviolet radiation can enhance people’s physical fitness and ability to resist infectious diseases, promote the synthesis of vitamin D3 in the body, maintain normal calcium and phosphorus metabolism and bone growth and development, accelerate wound healing, and improve immunity. When ultraviolet rays act strongly on the skin, full-blown dermatitis can occur, with erythema, itching, blisters, edema, etc. appearing on the skin; in severe cases, it can also cause skin cancer. According to statistics, the number of skin cancer patients has increased at a rate of 5% every year since 1983. This is related to the reduction of the ozone layer. For every 10% reduction in ozone concentration, the incidence of skin cancer in humans will increase by 26%.

Ultraviolet rays in the sun can be divided into three parts according to wavelength: UVA (315~400 nm), UVB (280~315 nm), and UVC (100~280nm). UVC is basically absorbed before it reaches the ground. The ultraviolet rays that directly act on the surface are mainly UVA and IUVB, that is, the ultraviolet part with a wavelength of 280 to 400nm. Therefore, protection against ultraviolet rays in this band is particularly important. As the second skin of the human body, work clothes should have a certain function of protecting the human body from the harsh external environment.

With the deepening of human understanding of the harm of ultraviolet rays, it is imperative to strengthen research on covering fabrics.

The protective effect of general fabrics is not very satisfactory, which requires dyeing and finishing workers to adopt certain technologies and processes to develop functional finishing agents that can effectively prevent ultraviolet rays.

1 UV resistance mechanism

The mechanism of UV protection of fabrics is divided into two types: reflection and absorption. When ultraviolet light shines on the fabric, part of it is absorbed by the fiber, part of it is reflected, and part of it is transmitted through the pores between the fabric fibers, or it may directly pass through the fiber itself. Only ultraviolet rays that pass through fabrics can radiate to the human body, and most of them are radiated directly to the human body, and the rest arrive through scattered radiation. Therefore, anti-UV fabrics mainly use shielding agents to cover fibers or fabrics to enhance the fabric’s ability to absorb or reflect UV rays. Commonly used UV shielding agents fall into two categories: inorganic and organic.

1.1 Inorganic UV shielding agent

Inorganic UV shielding agents, also known as UV reflectors, have a high refractive index and achieve the purpose of completely blocking radiation mainly by reflecting or refracting incident UV rays.

Some ultra-fine particles (such as nanopowders) have excellent UV resistance due to their small size effect and other characteristics. As dyeing and finishing auxiliaries, in order not to affect the color effect of fabrics, it is best to use transparent or white materials, so metal oxide powders are generally used, such as aluminum oxide (Al203), magnesium oxide (MgO), oxide Zinc (zno), titanium dioxide (Ti02), kaolin, etc., their ultraviolet shielding properties are closely related to the forbidden band gap in the structure. For example, the electronic structure of TiO2 is composed of a valence electron band filled with electrons and a conduction band formed by a channel without electrons. There is a forbidden band gap. The forbidden band gap is about 3.2eV, which is equivalent to the perfect energy at a wavelength of about 410nm. When the nano titanium dioxide is fully illuminated, all the electrons with the same energy as the forbidden band gap or slightly larger than the forbidden band gap energy are absorbed, and the electrons in the valence electron band It is excited to the conduction band, thus absorbing the ultraviolet part. Research shows that the ultraviolet transmittance of TiO2 with a particle size less than 100nm is less than 20%. ZnO is cheap and non-toxic, has a wider UV-shielding wavelength range than Ti02, has a smaller refractive index (n=1.9) than Ti02 (n=2.6), has a low diffuse scattering rate and high transparency. ZnO has also been proven to have anti-bacterial, anti-mold and anti-odor properties, so it has wider application prospects.

A variety of nanopowders added together can have a better shielding effect on ultraviolet rays. For example, if titanium dioxide, zinc oxide and silica are mixed, the first two only absorb at uvA and uVB, while silica has a reflectivity of up to 85% for ultraviolet rays in the range of uVA and uvB, and is perfect in ultraviolet and visible light. A long, highly reflective platform appears within range.

1.2 Organic UV shielding agent

Organic masking finishing agents are also called ultraviolet absorbers, which usually refer to organic compounds that can absorb ultraviolet rays with a wavelength of 270~400nm.

There are many varieties of UV absorbers at home and abroad. Commonly used products mainly include non-reactive, small molecule UV absorbers such as salicylates, benzophenones, benzotriazoles, Substituted triazines, substituted acrylonitriles and polymer UV absorbers. Salicylate compounds were used earlier, but are limited in application due to their poor stability; substituted triazines and substituted acrylonitriles are mostly used as complete stabilizers for polymers; currently there are prospects for progress They belong to benzophenones and benzoxadiazoles. These two are widely used in the industrial field due to their wide range of effective absorption wavelengths and good compatibility. At present, attempts are being made to commercialize them.��, place it under the standard UV finishing source, cover it with the fabric to be tested, turn on the finishing source, take the photo for a certain period of time, and then observe the color change of the sensitive dye-dyed base fabric under the covering. The smaller the color change, the smaller the color change. It means that the better the fabric to be tested is in blocking ultraviolet rays.

3.3 Ultraviolet intensity accumulation method

Use ultraviolet rays to completely illuminate the fabric placed on the ultraviolet intensity totalizer. According to the irradiation for a given time, the accumulated amount of ultraviolet rays passing through the fabric is measured and then calculated.

3.4 Intuitive method

Use covered fabrics and non-covered fabrics of the same material to cover the skin, and observe directly by irradiating ultraviolet rays.

3.5 Fabric UV resistance durability

In practical applications, anti-UV functional fabrics are also required to have excellent durability, that is, they can still maintain good anti-UV effects after multiple cleanings. You can refer to the national standard GB/T3921.3-1997 and use the following conditions to clean the fabric:

Soap liquid: standard soap flakes 5g/L;

Anhydrous sodium carbonate: 2g/L;

Temperature: (60±2)℃;

Time: 30min;

Liquor ratio: 50:1

The UV transmittance of the fabric is then measured to evaluate durability.

For the evaluation index of the quality of the covered fabric, the ultraviolet shielding rate is now adopted. Japan has proposed a standard that combines ultraviolet shielding rate and ultraviolet transmittance reduction rate. The reduction rate of ultraviolet transmittance is equal to the difference between the transmittance of traditional fabrics and the covered fabric and the percentage of transmittance of traditional fabrics. The standard proposed by Japan is that the fabric must first meet the requirement of 50% reduction in ultraviolet transmission, and then be graded based on the absolute shielding rate. Generally divided into three levels, those with a shielding rate of more than 90% are rated as Level A, those with a shielding rate of 80% to 90% are rated as Level B, and those with a shielding rate of 50% to 80% are rated as Level C. This is a good reference for domestic evaluation of the performance of masking fabrics.

4 Prospects and Outlook

The cover-up fabric meets people’s requirements for beauty and health care, and can also increase the added value of the product. With the improvement of people’s living standards and the enhancement of health care awareness, the cover-up fabric products have excellent Development value and broad market prospects. It has been started abroad for a long time, and we should catch up. When researching and developing, we should first conduct in-depth research and development on UV shielding agents and shielding fibers to form industrial production capabilities; secondly, we should adopt different finishing methods according to the use of the products. Improve its taking performance. For example, when post-treatment is used, fabrics for work clothes should be impregnated to improve their breathability, while fabrics for parasols and curtains can be treated with PU coating; at the same time, it should be noted that people have begun to propose properties for synthetic fibers. Multiple functional requirements, and ceramic micropowders and metal oxides used as ultraviolet shielding agents are also used in other functional finishing such as antibacterial, deodorizing, and far-infrared health care of fabrics. Therefore, when developing finished fiber fabrics, it is best to It can provide various functions such as cooling, antibacterial and deodorizing, far-infrared health care or fire prevention, and anti-static to further enhance its use value.

AAASDFWETGD

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA