The difference between ordinary anti-static fabrics and ultra-clean anti-static fabrics

The anti-static ultra-clean fabric used in anti-static work clothes is usually called “conductive silk”. In fact, this statement is not strict. According to its own technical characteristics, conductive silk can be divided into those suitable for static elimination (ESD) and those suitable for clean rooms (Clean Room).

Room), only conductive silk suitable for clean rooms can be called anti-static ultra-clean fabrics. What is anti-static fabric? Fabrics that have been treated with anti-static finishing can be called anti-static fabrics.

The anti-static finishing methods for anti-static fabrics usually include:

①The fabric is finished with an antistatic finishing agent;

② Fiber graft modification, blended chemical fiber fabrics and interlacing of hydrophilic fibers for the purpose of improving fabric hygroscopicity;

③Blended chemical fiber fabric or inlaid conductive fiber;

The mechanism of action of the first two methods is to increase the moisture regain of fabrics, reduce insulation, and accelerate electrostatic leakage. Therefore, if the finishing effect is not durable or not significant in a dry environment or after multiple cleanings, it is usually used on general workwear fabrics. Only the third method can permanently and efficiently solve the static problem of fabrics, so it is currently widely used in the production of anti-static workwear. The fabric is finished with an antistatic finishing agent.

Antistatic fabrics can be woven fabrics, such as conductive silk, antistatic T/C fabrics, or knitted fabrics, such as antistatic knitted gloves, antistatic knitted underwear, etc. . In addition to meeting the general technical standards for fabric products, anti-static fabrics must also have good anti-static properties to meet product production and safety needs. For technical requirements, please refer to GB12059-89 “Performance of Synthetic Fiber Antistatic Silk for Electronic Industry”

The difference between ultra-clean fabrics and general anti-static fabrics in anti-static workwear

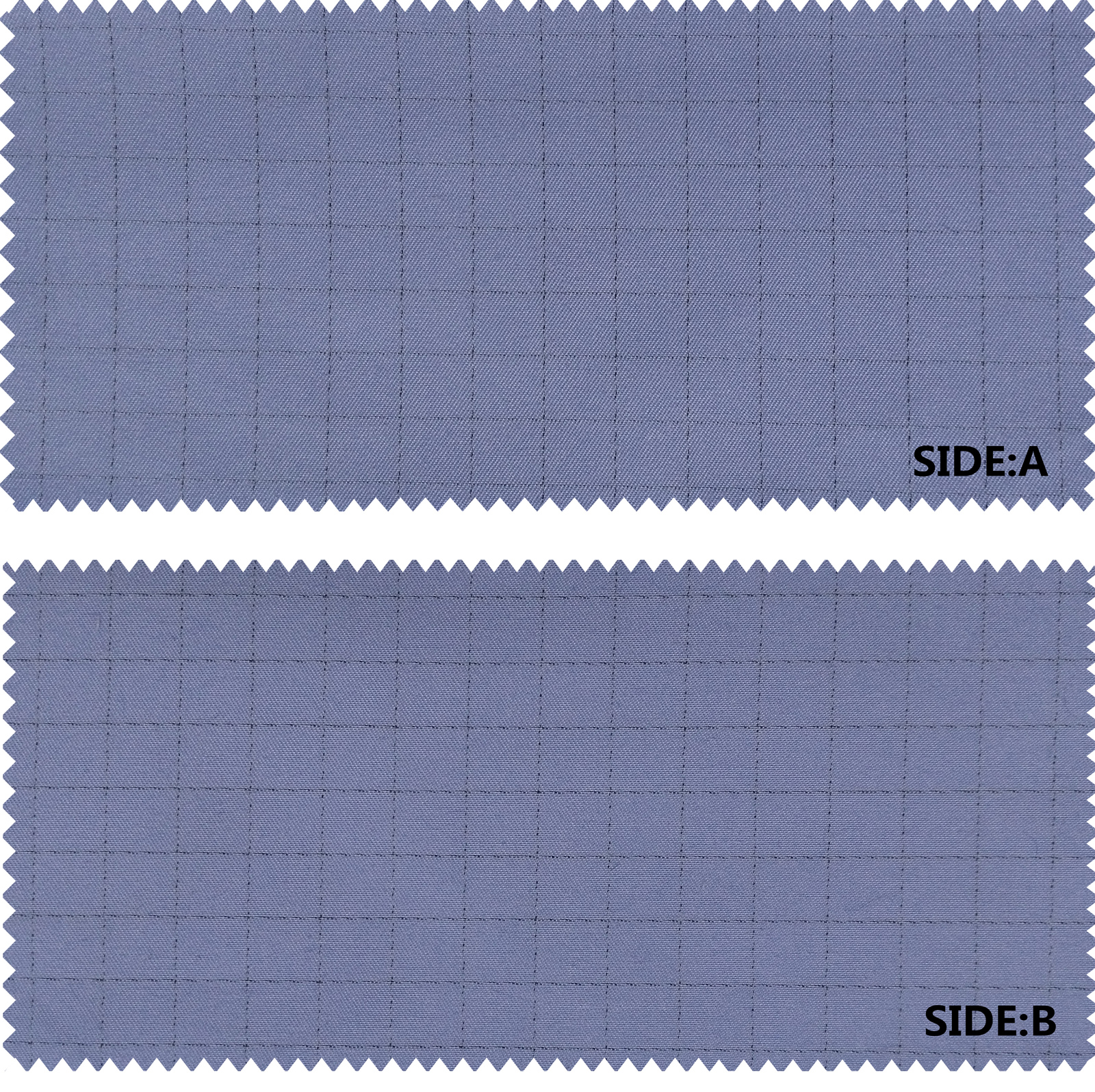

The difference between anti-static ultra-clean fabrics and general anti-static fabrics mainly lies in the concept of “ultra-clean”. Anti-static ultra-clean fabric must have the following three characteristics at the same time:

With anti-static function: static electricity will absorb dust and make it difficult for the adsorbed dust to be blown away during wind shower. Therefore, the primary feature of antistatic ultra-clean fabrics is their antistatic properties. At the same time, this antistatic performance must be long-lasting and efficient, and not significantly degraded by daily cleaning and friction.

The fabric itself does not generate dust: Since it is worn in a clean room, it is required that the cloth cannot become a source of dust in the clean room. This determines that ultra-clean fabrics can only be made of chemically synthesized long fibers. Production. Natural short fibers such as cotton, linen, and silk cannot be used in ultra-clean fabrics, although these raw materials can make the fabrics more wearable. At the same time, it is required that the chemical fiber filament selected must also strictly control the amount of dust generated. Generally speaking, fully consumed polyester filaments are not suitable for weaving anti-static ultra-clean fabrics. Because the disinfectant-titanium dioxide added in polyester production will become a source of pollution.

The fabric must have good dust filtration properties: Dust in clean rooms mainly comes from the air flowing indoors and the human body moving indoors. When the equipment conditions are determined, improving cleanliness means controlling the tiny dust generated by the human body in the clothing to the maximum extent, allowing it to pass through the fabric and enter the air. This is the so-called dust filtration rate of cloth. Improving the dust filtration rate comes at the expense of the breathability of the fabric. Therefore, knitted fabrics and loosely woven woven fabrics are not suitable for clean rooms.

AAADFGRTJUYKYU

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA