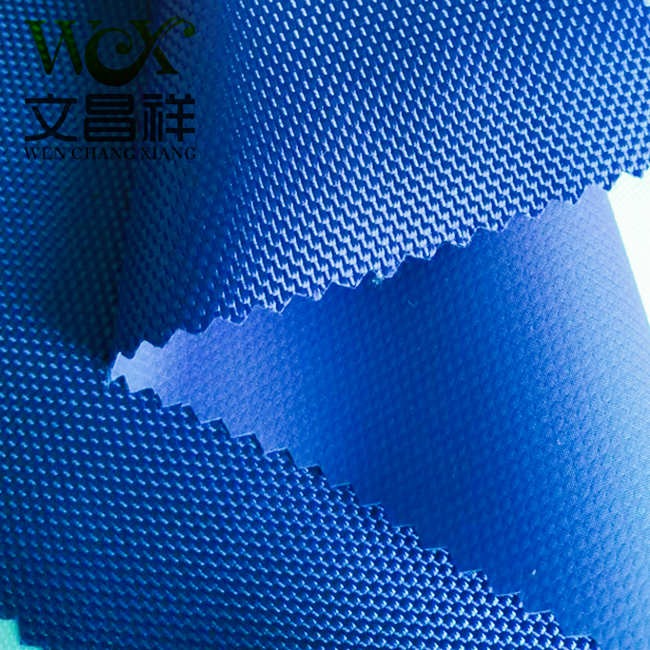

1680D double-strand Oxford cloth is made of two 420D nylon yarns that are wound and twisted. Combined into one twisted 840D silk, because the weaving method is double warp and double weft, the two 840D silks are 1680D double-ply Oxford cloth.

1680D Oxford cloth has a better touch and better waterproof performance after post-processing such as calendered PVC, polyurethane, and PU coating. 1680D also has multiple specifications and style changes. The difference lies in the changes in yarn count density and weight during the weaving process. There are two types of dyeing: liquid flow cylinder dyeing and flat cylinder dyeing. Liquid flow cylinder dyeing has high color fastness (dry grinding and wet grinding are both above level 4), small color difference, strong graininess and good gloss.

1680D Oxford cloth has strong wear resistance, tear resistance, high density, and is also waterproof. The good luster gives it an aura of nobility, making it easy to walk in the world of nobility. It has always been the best choice for high-end outdoor products and luggage fabrics. The water-sprayed surface of the 1680D waterproof Oxford cloth only needs to be wiped off gently, and the water droplets will not penetrate into the interior; the grinding wheel scratch test showed that the fabric did not wrinkle, pill, or break, etc.; it was woven using a special process The method is used to create high-strength and flexible fabrics that can prevent rupture caused by blunt impact.

What are the specifications of Oxford cloth? Such as 1680D, 1200D, 900D, 600D, 420D, 300D, 210D, 150D and other Oxford cloth. Function classification of Oxford cloth: fire-retardant cloth, waterproof Oxford cloth, PVC Oxford cloth, PU Oxford cloth, camouflage Oxford cloth, fluorescent Oxford cloth, Printed Oxford cloth, composite Oxford cloth, etc.

</p