Judge by oxygen index: combustion requires oxygen, and the oxygen index is the amount of oxygen required for fiber burning expression, so the flame retardant performance of Oxford fabric can be determined by measuring the oxygen index. The higher the oxygen index, the higher the oxygen concentration required to maintain combustion.

That is to say, the more difficult it is to burn: this index can be expressed by the minimum volume percentage of oxygen required for the sample to maintain candle-like combustion in a nitrogen and oxygen mixed gas. Indicators: If the oxygen index is less than 20%, it is a flammable fiber; if the oxygen index is between 20 and 26%, it is a flammable fiber. The oxygen index between 26 and 34% is a flame-retardant fiber, and the oxygen index above 35% is a non-flammable fiber.

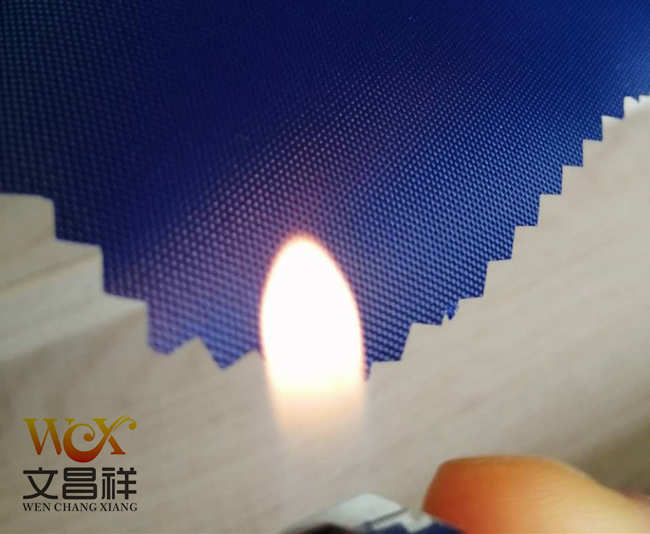

First, you can look at its burning performance, which can be distinguished from the burning rate of flame-retardant Oxford fabric. It means that the Oxford cloth fabric that has been flame-retardant is exposed to the flame for a certain period of time according to the prescribed method, and then the flame is removed, and the time for continuous fire burning and non-flame burning time is measured, as well as the degree of damage to the Oxford cloth fabric. The shorter the flaming burning time and the flameless burning time, and the lower the degree of damage, the better the flame retardant performance; on the contrary, the flame retardant performance is poor.

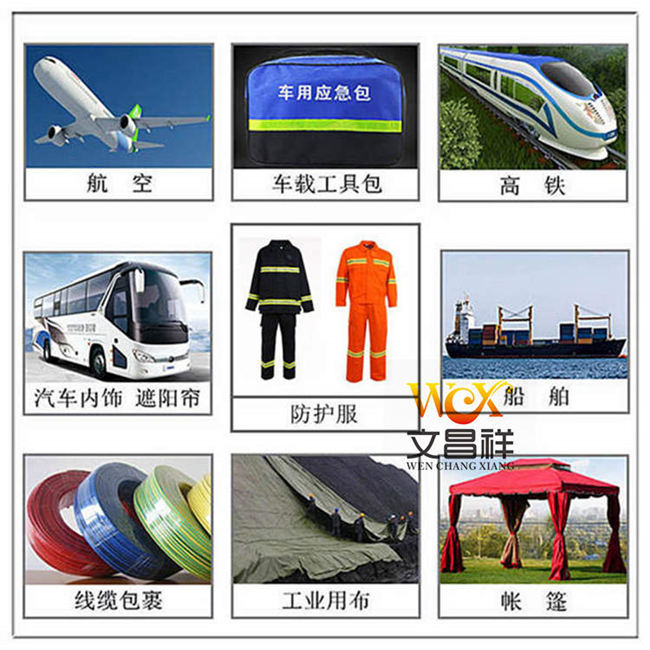

What are the specifications of Oxford cloth? Such as 1680D, 1200D, 900D, 600D, 420D, 300D, 210D, 150D and other Oxford cloth. Function classification of Oxford cloth: fire-retardant cloth, waterproof Oxford cloth, PVC Oxford cloth, PU Oxford cloth, camouflage Oxford cloth, fluorescent Oxford cloth, Printed Oxford cloth, composite Oxford cloth, etc.

</p