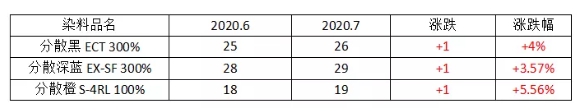

From July 1st, disperse black ECT will rise by 300% to 26 yuan/KG, and all regular series of disperse dyes will rise!

Disperse dye prices will be difficult to rise later

The news of dye price increases has been long gone! Looking back, the most recent news of a dye price increase was in February this year. Later, affected by the epidemic, not only the demand for dyes from domestic printing and dyeing factories decreased, but overseas demand has also been weak, and the price of dispersed black dropped to 25 yuan/KG. Since May, with the increase in fabric orders from downstream printing and dyeing factories, dye prices have stopped falling and stabilized. The improvement of the epidemic situation has promoted the recovery of dye prices. Therefore, the price of dispersed black can be raised to 26 yuan/KG in July.

On June 24, the official website of the Xiangshui County People’s Government issued an announcement “Announcement on Jiangsu Lianhua Technology Co., Ltd. and Lianhua Technology (Yancheng) Co., Ltd. passing the county-level acceptance of production resumption”, marking the chemical production in Xiangshui County. The enterprise’s resumption of production is progressing steadily, and the resumption of production is expected!

This news has a greater impact on the dye industry. If the Xiangshui Industrial Park resumes production, the supply of dyes will further increase, and its prices may be difficult to increase. pick up. Moreover, the correction of dyes this time is not large, and the impact on downstream printing and dyeing enterprises is almost minimal.

Dyeing costs have been very stable since 2019

This round of price increases for disperse dyes The direct impact is not big. Unlike in previous years, printing and dyeing factories usually issued notices to increase dyeing fees due to rising dye prices. At present, there are almost no price increase notices from any printing and dyeing factories. Looking back on recent years, since the beginning of 2019, the dyeing fees of printing and dyeing factories have hardly been adjusted and have returned to the initial very stable state. The first and most direct reason is naturally the price of dyes. Although dye prices have fluctuated to some extent since 2019, they have been on a downward trend throughout the year. In short, the price of dyes continues to fall, and the high price no longer exists. Therefore, the cost pressure on dyes in printing and dyeing factories can be slightly released, and naturally there is no need to increase dyeing fees.

The second point, which is also a very important reason, is that the number of orders received by printing and dyeing factories has seriously declined, and they are in a state of not having enough to eat for a long time! Since 2019, the operating rate of printing and dyeing factories has been very rare at 100%. Especially this year, the average operating rate is only about 60%. In such a situation of long-term lack of orders, it is impossible for printing and dyeing factories to increase their external quotations for dyeing fees. Instead, private preferential policies have emerged, and the preferential prices for customers with different order quantities are also different. In the situation of “more monks and less rice”, the competitive pressure of printing and dyeing factories is increasing. In order to retain customers, the only way is through price concessions.

A printing and dyeing factory with hundreds of dyeing vats currently maintains an operating rate of 90%, sometimes up to 100%. The overall operating rate in Wujiang is only about 60%. Why can this printing and dyeing factory have such a high operating rate? Through the editor’s inquiry, I learned that this printing and dyeing factory originally had a slightly higher dyeing fee due to its better quality. This year, in order to retain customers, it gave a larger discount, so the business volume has increased significantly.

Dyeing orders are lacking, and the operating rate may not be at full capacity

Although the price of dyes has an upward trend in the later period, it may not be able to drive the price of dyeing fees. The increase in dyeing fees depends more on the number of downstream dyeing orders. Affected by the epidemic this year, the entire textile industry has been greatly affected. Business volumes in all links have been sluggish due to lack of orders. The same is true for printing and dyeing factories. The operating rate has been insufficient for a long time, and the daily warehouse volume has dropped from one million meters to two to three million meters. If the printing and dyeing market as a whole is underfed and competition among peers is fierce, no company will raise dyeing fees and reduce competitiveness. However, it cannot be ruled out that some printing and dyeing giants have strong competitiveness and often take the lead in raising prices. Small businesses often do not have the ability to keep up with the increase, and the pressure brought by costs is absorbed by themselves.

</p