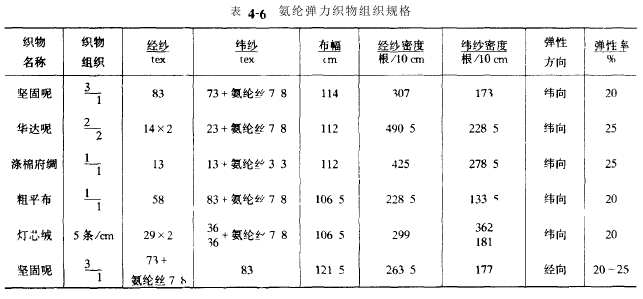

Design of main structural parameters of elastic fabric

1. Things to note when designing elastic fabrics

(1) In addition to making the fabric achieve the required wind characteristics, product specification design also determines the elasticity that the fabric can obtain in the warp and weft directions. When designing, we must first clarify the purpose of the fabric, determine the required elasticity in the warp and weft directions of the fabric, and comprehensively consider factors such as raw materials, linear density, organization, and density, as well as the spandex draft multiple, spandex content, and twist in the spinning yarn.

(2) The warp and weft yarns are made of spandex blended chemical fiber fabric yarn. Due to the shrinkage rate of spandex, the yarn in the fabric is actually in an unstable mechanical equilibrium state. Elastic changes in any direction will affect the elasticity in the other direction. Therefore, the longitudinal and latitudinal elasticity should be balanced during design.

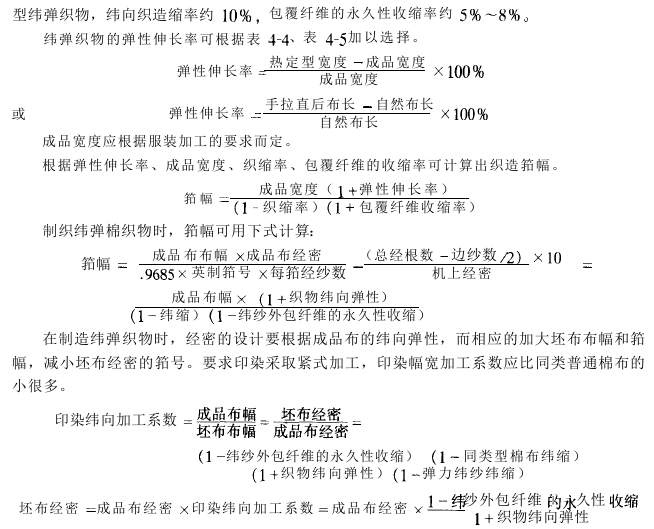

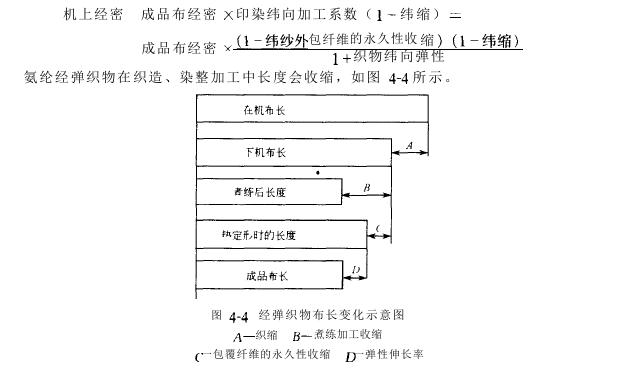

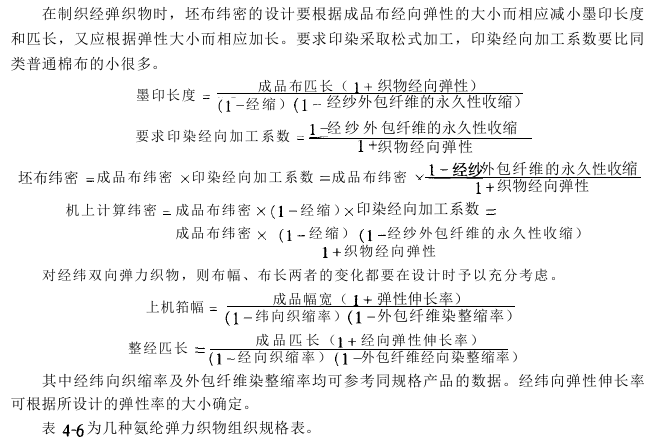

(3) The retraction of the spandex yarn in the relaxed tension state will cause the fabric to shrink significantly after the warp and weft are lowered into the machine and during the dyeing and finishing process. Therefore, during process calculation, the reed width and warping length should be increased according to the warp and weft elasticity of the finished product, and other data should be adjusted accordingly.

(1) Selection of fabric weave

Fabric weave directly affects the appearance effect of the fabric, and the length of its floating lines Directly affects the fullness and elasticity of the fabric.

Tests have proven that fabric structure and density are important factors affecting the warp and weft elasticity of fabrics. The fewer intersecting points on the spinning yarn (the longer the floating length of the spinning yarn), the larger the gap between the yarns (the longer the floating length of the spinning yarn). The smaller the yarn density), the greater the elastic shrinkage of the fabric, which is manifested in the greater elastic elongation of the fabric.

In order to make the fabric surface flat, the weave should be selected so that the number of staggered points on the spinning yarns of the same system is as equal as possible, and the floating length should not be too long, preferably less than or equal to 3, which will help to exert elasticity. Elastic elongation of fabric. For example, square weave, 2/2 twill, plain weave, 3/1 twill, 3 1/1 1 change twill, etc. can be used.

(2) Selection of warp and weft density

Warp and weft density is an important factor in determining the appearance, thickness, weight, elasticity, and feel of a product. Especially for elastic fabrics, it directly affects the effective width and shrinkage of the fabric. If the density is too high, the fabric will be too stiff, affecting comfort; if the density is too small, the fabric will shrink too much and the dimensional stability of the fabric will be poor. How to solve this critical problem, the important principle is that the warp and weft density of natural cotton cloth should be changed accordingly according to the change of elastic elongation or effective width. If the density of the natural cotton fabric is too high (the warp elastic fabric is mainly weft density, and the weft elastic fabric is mainly warp density), the fabric will have no room for shrinkage during wet and heat finishing, and the estimated elastic elongation and hand feel will not be obtained; but the density If it is too small, it will also affect the intrinsic quality of the fabric.

The design of density is related to the shrinkage of the fabric in each finishing process. However, the factors that affect shrinkage are quite complex and are related to the type of outer fiber, linear density of spinning yarn, twist coefficient of spinning yarn, fabric texture, structure and process parameters of each process.

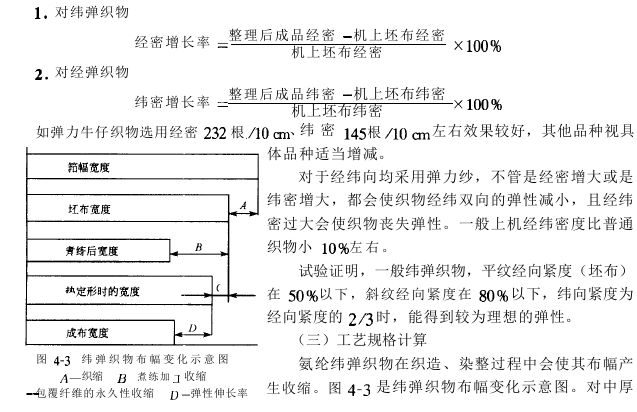

Therefore, design and calculation data such as warp length, effective width, reed width, warp density, and weft density should be determined after trial weaving. The change from machine density to cloth density can be expressed by warp density growth rate or weft density growth rate.

AAANHGMKJLOI87