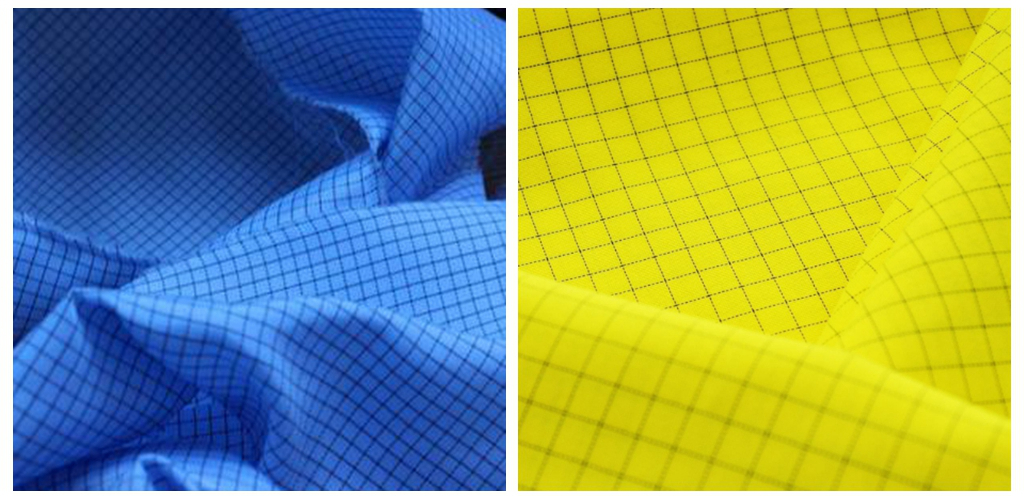

Processing methods of anti-static fabrics

Therefore, if the finishing effect is not durable or not noticeable in a dry environment or after multiple cleanings, it is usually used on general workwear fabrics. Only the third method can permanently and efficiently solve the static problem of fabrics, so it is widely used in the production of anti-static workwear. The fabric is finished with an antistatic finishing agent. The types of anti-static fabrics include: anti-static silk (conductive silk) and anti-static ultra-clean fabrics, anti-static tc fabrics, anti-static tr fabrics, anti-static cvc fabrics, anti-static Cotton fabrics, etc.

There are usually several methods for finishing anti-static fabrics:

, the fabric is finished with an antistatic finishing agent

Second, fiber grafting modification and hydrophilic fiber blended chemical fiber fabrics and interlacing for the purpose of improving fabric hygroscopicity

Third, blended chemical fiber fabrics or inlaid conductive fibers; the mechanisms of the first two methods are to increase the moisture regain of the fabric, reduce the insulation, and accelerate electrostatic leakage.

AAAVBBCNVM,N. KJO

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA